Diamond concrete chain sawing is the most effective tool for many construction and demolition jobs in the Kansas City area. Cutting through hard materials like stone, concrete, asphalt, and bricks to segment concrete or create openings such as egress windows and doorways is common. In order to accomplish this, operators use diamond saw blades that are coated with synthetic diamond powder, an abrasive material that creates the necessary friction.

Diamond concrete chain sawing is the most effective tool for many construction and demolition jobs in the Kansas City area. Cutting through hard materials like stone, concrete, asphalt, and bricks to segment concrete or create openings such as egress windows and doorways is common. In order to accomplish this, operators use diamond saw blades that are coated with synthetic diamond powder, an abrasive material that creates the necessary friction.

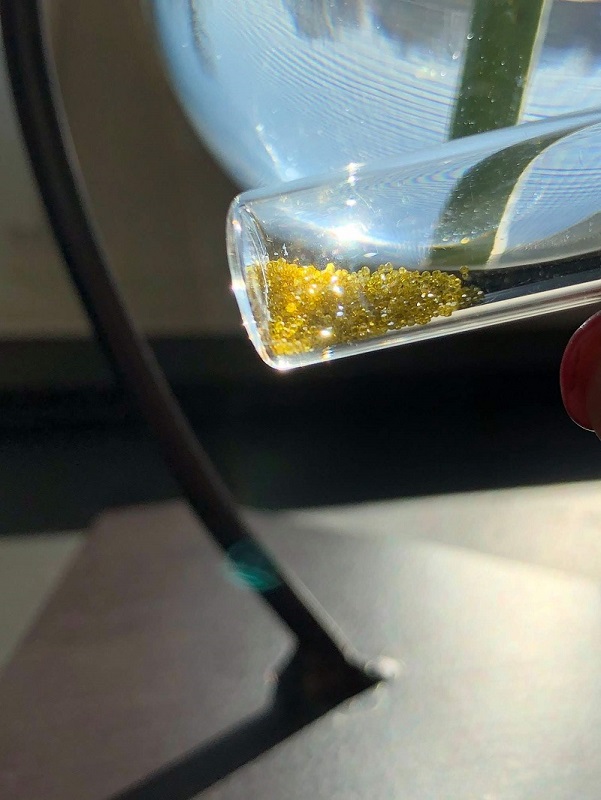

Synthetic diamond powder (also referred to as a laboratory-grown diamond) is made of the same material as natural diamonds, but is different from both natural diamond, which is created by the geological process, and diamond stimulant, which is made of non-diamond material. Using synthetic diamond-coated saw blades, concrete chain sawing can cut through the hardest of materials for all kinds of construction-related purposes, such as bridge abutments, elevated structures, dams, parking lots, foundations, and more.

When undertaking a concrete chain sawing job in Kansas City, proper use and maintenance of the chainsaws are elemental to ensure continued operations. For instance, the saws must be run with water in order to keep the chain cool and prevent premature chain-stretch. Also, water prevents excessive wear on the diamond chain and overheating of the saw, and minimizes any dust created. Typically, a dedicated water source is used, either from a water truck or a spigot.

A mix of high-quality synthetic oil and higher-octane gas is used in the saws for the best performance. Keeping the saw’s chain at the right tension is also critically important to the longevity of the saw’s chain and powerhead. A properly tensioned chain needs to be just a little loose on the guide bar but still tight enough to prevent pulling the drive links out of the bar nose. Problems can be avoided when the operator periodically checks the tension of the chain to make sure there are no tight spots and loosening the chain slightly when needed. Likewise, when the chain is too loose, the chain must be adjusted to the proper tension.

Further, after each use, the powerhead, bar, chain, and starter rewind should be sprayed off with pressurized water to rinse out and wash away concrete slurry from the saw, followed by praying the saw with a lightweight lubricant, such as WD40, to prevent rust and prepare the saw for the next concrete chain sawing job. Following these few simple points will prolong the life of the powerhead and give operators hours of trouble-free use.

When it comes to concrete chain sawing, all of our saws and equipment are consistently maintained to ensure no down-time on the job. Fine Cut operators are able to cut masonry and concrete structures for creating joints, windows and doorways, cut floor slabs, walls, retaining walls, concrete roof decks, and demolition cutting. Contact us today for more information or to request an estimate for your Kansas City area concrete chain sawing project.