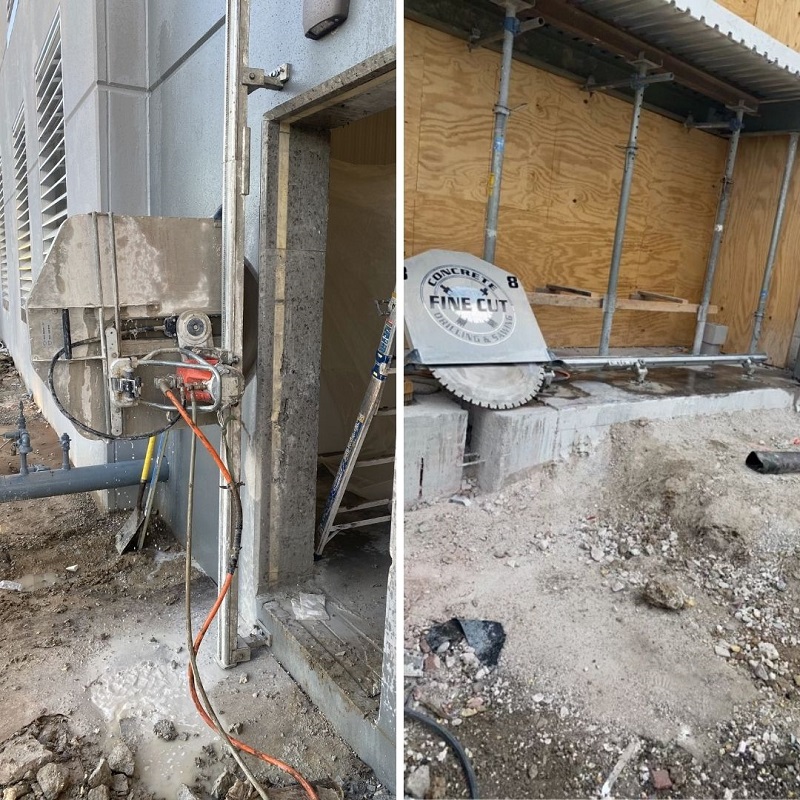

Concrete wall sawing is a critical step for opening a spot on a wall to create new doorways, windows, or an HVAC unit. Wall saws are also commonly referred to as track saws and typically run on hydraulic or electric power. The wall saw utilizes a diamond blade on a track-mounted system, which allows for precise cuts in both concrete and masonry structures. Wall saws are lighter in weight to allow them to be transported easier and have the power to saw effectively either horizontally or vertically. Some of the benefits of concrete wall sawing are:

Concrete wall sawing is a critical step for opening a spot on a wall to create new doorways, windows, or an HVAC unit. Wall saws are also commonly referred to as track saws and typically run on hydraulic or electric power. The wall saw utilizes a diamond blade on a track-mounted system, which allows for precise cuts in both concrete and masonry structures. Wall saws are lighter in weight to allow them to be transported easier and have the power to saw effectively either horizontally or vertically. Some of the benefits of concrete wall sawing are:

- Less downtime;

- Less noise, dust, and debris;

- Precision cutting;

- Limited-access cutting;

- Maintains structural integrity.

A benefit of concrete wall sawing is that it can also be performed from both sides of the wall, and to a total depth of up to 60”. Typical applications for concrete wall sawing include flush-cutting against other wall surfaces, bevel cutting for a chamfered edge, straight, and smooth-finished openings in walls, ceilings, and floors, as well as accurately sized, fixture ready openings in foundations, dams, levies, and precast walls. Further, it can accommodate openings that require a specific angle through the concrete, and for thicker walls and floors.

Concrete and masonry are the two main materials operators have to saw through. They are often required to cut through stone, cinder block, concrete, structural concrete, and asphalt. Fine Cut’s operators are able to determine when to begin concrete wall sawing, and what to do once they get started. After first determining what the particular job is needed for, they must select the specific equipment required, such as a diamond blade, and tracks to hold the blade in place and guide it while it saws. They must also determine how deep the cuts need to be, and whether the job calls for an angled cut or not.

Operators must always stay aware of what could happen while the sawing is in progress, which includes overcutting. The blade offset value is used in calculating the distance the blade must travel past a corner – if set too low, corners will be rounded. One way an operator avoids overcutting is by employing a different concrete wall sawing technique, such as hand sawing, which minimizes the chances of an overcut occurring. With this technique, when overcuts do happen, they can be trimmed with the use of a handheld chainsaw.

Fine Cut USA is proud of our expert operators and the dedication they have for safety in the workplace. They are trained in safety practices and are fully aware of how to handle equipment and potential concrete wall sawing situations that could occur during a project. We have earned an outstanding reputation for consistency, reliability, and cost-effective solutions throughout the greater Kansas City metro, Springfield or Branson, Missouri, Fayetteville or Bentonville, Arkansas, and select cities in Kansas. Many major construction and demolition projects in the area have since relied on our concrete wall sawing, drilling, and cutting services. Our team of professionals is committed to conducting our business with integrity and honesty, a solid work ethic, and providing high-quality services. To request a quote, contact us today!

Fine Cut USA 816-540-5787

Missouri Kansas Arkansas